If you’re researching small carbonization machines, you likely want to turn biomass waste into valuable biochar efficiently and profitably.

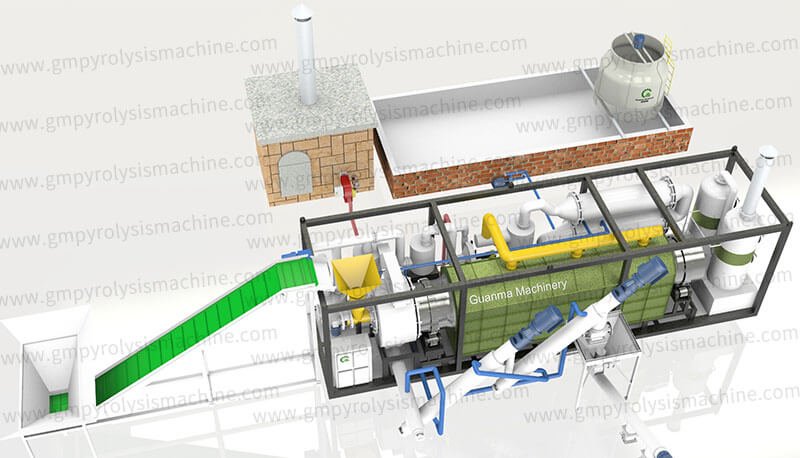

Small carbonization machines are designed to convert various biomass materials (like wood chips, rice husks, agricultural waste, coconut shells, and sewage sludge) into biochar through a high-temperature pyrolysis process in a compact, often portable, system. Their rising global demand is fueled by the growing need for sustainable waste management solutions and the valuable output they produce.

What Truly Matters When Choosing a Small Carbonization Machines?

While many suppliers list basic specifications, understanding these key aspects in detail will ensure you select a machine that delivers optimal performance and return on investment.

1. Core Technical Specifications & Performance

heating method

direct vs. indirect heating impacts efficiency and product quality.

operating temperature range

precise control is crucial for producing different biochar grades.

reactor material

high-temperature resistant alloys ensure longevity.

rotation speed

if applicable, for even carbonization.

continuous vs. batch processing

affects output and labor requirements.

A higher capacity model might seem better, but align it with your actual raw material availability.

2. Advanced Operational Considerations

Automatic temperature control systems

Enhance consistency and safety.

Sealed discharge systems

Prevent oxygen ingress during unloading, protecting biochar quality and minimizing fire risk.

Integrated cooling systems

Allow for faster processing cycles.

Remote monitoring capabilitie

Remote monitoring capabilities are a modern advantage, enabling operational checks from a distance.

3. Environmental Compliance and Safety

This is critical for long-term operation. Examine the emission control systems in detail. Effective machines include advanced cyclone dust removers, spray dedusting systems, and odor scrubbers to ensure smoke and gases meet international environmental standards (like CE certification for Europe). Pressure relief valves and automatic shutdown mechanisms in case of overheating are essential safety features.

4. Output Quality and Versatility

The true value lies in the biochar. Discuss the expected fixed carbon content and specific surface area (SSA) of the produced biochar with suppliers—these determine its market value and effectiveness for applications like soil amendment or water filtration. A superior small carbonization machine handles diverse feedstock without compromising efficiency or requiring extensive pre-processing.

Unlocking Profitability: The Tangible Benefits of Investing in a Small Carbonization Machine

Understanding the financial upside is crucial for your decision.

Revenue Streams from Biochar

High-quality biochar is in demand in agriculture (soil enhancement), industry (as a fuel source or filtration medium), and even for carbon sequestration projects. You transform waste into a sellable product.

Significant Waste Reduction and Cost Savings

Dramatically reduce or even eliminate costs associated with waste disposal, storage, and transportation for agricultural, forestry, or food processing operations.

Energy Independence and By-Product Utilization

Some advanced models can recycle the syngas produced during pyrolysis to fuel the process itself, drastically reducing external energy needs and operating costs. Some systems can also collect bio-oil, another potential by-product.

Enhanced Sustainability Profile

Using a carbonization machine demonstrates a commitment to circular economy principles, which can improve your brand image, appeal to environmentally conscious partners, and potentially qualify you for green certifications or incentives.

Ready to see the difference a well-engineered small carbonization machine can make? Contact us today for a detailed quotation and a personalized consultation to discuss your specific raw materials and output goals. Let us help you turn your waste into wealth.