Our waste oil distillation plant converts almost any dirty lubricant—used engine oil, pyrolysis oil, sludge oil, fuel oil into qualified diesel oil, base oil or other valuable petroleum products.

Raw Materials Processed by Waste Oil Distillation Plant

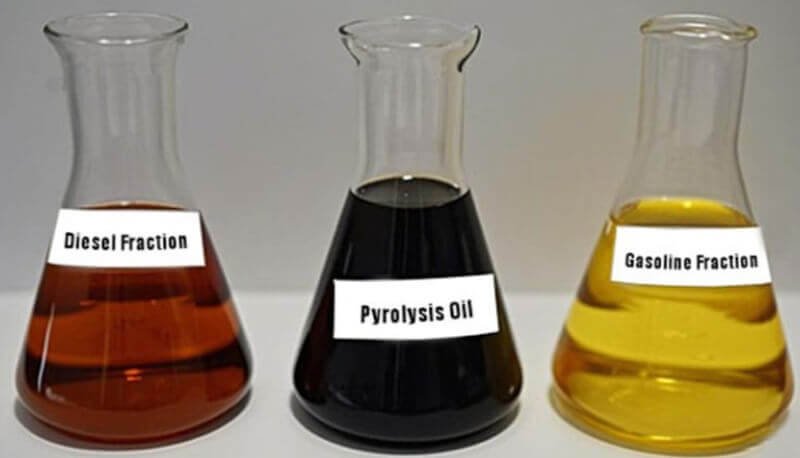

Final Products of Waste Oil Recycling Equipment

Diesel oil: The main product, which can be used in diesel engines, generators, boilers, etc.

Base oil: Can be further processed into lubricating oil after waste oil refining plant, with high market value.

Asphalt residue: Can be used for road construction, waterproof materials, etc.

| Raw Materials | Oil Output Rate | ||

|---|---|---|---|

| Waste Engine Oil | 85% | gasoline | 10% |

| diesel | 75% | ||

| Heavy oil and others | >15% | ||

| Plastic Oil | 85%~90% | gasoline | 20%~25% |

| diesel | 65%~70% | ||

| Heavy oil | 10% | ||

| others | 5% | ||

| Tire Oil | 75%~80% | gasoline | 10% |

| diesel | 65%~70% | ||

| Heavy oil and others | 20% | ||

| Note: the oil yield will be different according to the different raw materials, please tell us your materials. | |||

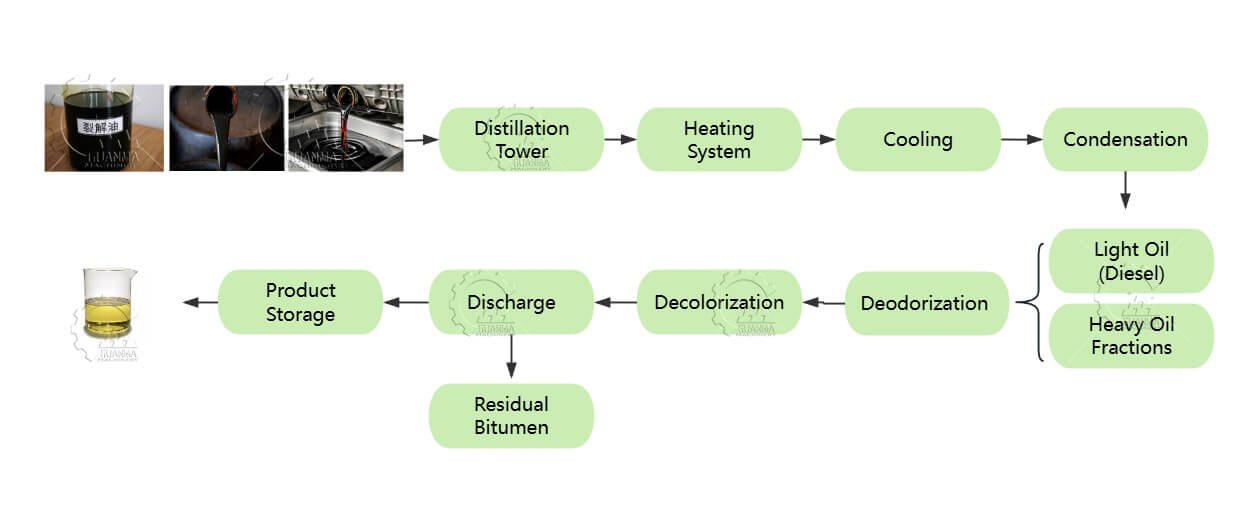

Waste Oil Distillation Process

Many customers may ask what is oil distillation? The process, central to what is oil distillation, involves controlled heating and separation:

1. Raw Material Pretreatment

First, the waste oil is filtered to remove impurities, water and mechanical impurities, ensuring the purity of the raw materials entering the distillation tower and improving the distillation effect.

2. Heating and Distillation

The pretreated waste oil is sent to the distillation tower, and heated to a certain temperature by the heating system. Under vacuum conditions, the waste oil is vaporized and separated into different fractions according to the boiling point of different components.

3. Cooling and Condensation

Vapors pass through a multi-stage condensation system, liquefying into light oil (diesel) and heavy oil fractions.

4. Deodorization & Decolorization

The distilled oil undergoes refining to remove impurities and odors, improving color and quality.

5. Discharge

Residual bitumen is automatically discharged after distillation is complete.

6. Product Storage

The final qualified products (diesel oil, base oil, etc.) are stored in the product tank for later use or sale.

| Model | ODP-6 | ODP-10 |

| Capacity | 6T/D | 10T/D |

| Oil Yield | 5.1T/D | 8.5T/D |

| Raw Materials | Crude oil, waste oil, fuel oil, used engine oil | |

| Heating Materials | Oil, LPG, natural gas, wood, coal, etc. | |

| Power | 20KW | 36KW |

| Cooling Method | Water cooling | |

| Operating Pressure | Normal and Vacuum | |

Key Advantages of Our Waste Oil Distillation Plant

Compared with other similar waste oil distillation machine on the market, our waste oil distillation plant has the following obvious advantages:

High Oil Yield

Advanced design ensures a diesel yield of up to 85-90% from qualified feedstock.

Excellent Fuel Quality

Produces clear, low-sulfur diesel that meets market standards.

Customizable Capacity

We customize machines with different capacities according to customer needs, using different heating system for batch-type plant and auto continuous plant.

Environmentally Friendly

Fully sealed system with advanced fume cleaning (scrubber, ceramic ring filter) ensures emissions meet environmental regulations.

Energy Efficient

Innovative heat exchange technology recycles thermal energy, significantly reducing fuel costs.

Safe & Automatic

Equipped with safety valves, pressure gauges, and alarm systems. PLC control system allows for easy semi-automatic or automatic operation.

Durable Construction

Manufactured from high-grade boiler steel, ensuring long service life and stable performance.

Why Choose Guanma Machinery's Waste Oil Distillation Plant Supplier?

Professional R & D team

We have a professional R & D team that can continuously optimize and upgrade the equipment according to the needs of customers and market changes.

Customized Solutions

We offer Waste Oil Distillation Plants tailored to your specific raw material, capacity needs (from 5 TPD to 100 TPD), and site requirements.

Comprehensive Service

From project consultation, layout design, installation guidance, to operator training and after-sales support.

Competitive Price

Guanma machinery waste oil distillation machine manufacturer, We have our own factory, Providing customers with high-quality products at competitive prices. For waste oil distillation plant price, please contact us for the latest quotation.

Global Market Recognition

Our waste engine oil recycling machine has been exported to more than 50 countries and regions, such as Southeast Asia, Africa, South America, etc., and has won unanimous praise from customers.

If you are interested in our pyrolysis oil distillation plant, continuous tyre pyrolysis plant or other continuous carbonization pyrolysis machine, please feel free to contact us.

Customer Visiting

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)